News Story

Rapidly evolving ‘smart marble’ sensors hold promise for monitoring pharmaceutical industry bioreactors and beyond

Two new papers published in Sensors and Actuators B: Chemical and the Journal of Microelectromechanical Systems chronicle recent advances a University of Maryland team has made in developing “smart marbles,” neutrally buoyant sensors that can wirelessly transmit readings inside a bioprocessing reactor. These sensors, also known as bPods (bio-processing online devices) offer the promise of real-time in situ monitoring of cell culturing parameters such as dissolved oxygen.

The pharmaceutical industry uses large, fully-automated bioprocessing reactors to rapidly mass produce a wide variety of mammalian and bacterial cell cultures for biologics, antibiotics and vaccines. For the cultures produced to be of high quality and effective, processes within these reactors must be closely monitored for uniformity.

Existing commercial monitoring solutions, such as inline instrumental probes, are limited to single-point measurements that are then used as an averaged value for the entire bioreactor. However, this technology cannot capture the distribution of process parameters throughout the bioreactor. They are unable to detect the presence of gradients or heterogeneity in physical parameters (i.e. temperature/pH) and the concentration of compounds of interest (i.e. glucose/oxygen) throughout the bioreactor. A sensor with the capabilities of a bPod could permeate and travel through bioreactor flows and continuously record variations in key parameters. It would provide high-precision bioprocess monitoring that could help to achieve a more uniform and effective product.

Since 2017, a University of Maryland research team has been working on a bPod platform with funding from the National Science Foundation and the Advanced Mammalian Biomanufacturing Innovation Center (AMBIC). In 2018, a prototype the size of a baseball was presented and won third prize at a 2018 AMBIC industry consortium meeting. Since then, the Maryland researchers have been refining and reducing the size of their innovative sensor. Their most recent work is chronicled in the two papers published this spring.

“The 26 world-leading biopharmaceutical companies that are part of AMBIC are aggressively pursuing advanced and innovative analytical technologies to streamline manufacturing processes,” says Professor William Bentley of the Fischell Department of Engineering and Robert E. Fischell Institute for Biomedical Devices. “Our bPod ‘smart marbles’ platform is being viewed as a potential game-changer.”

Electrochemical Dissolved Oxygen Sensor-Integrated Platform for Wireless In Situ Bioprocess Monitoring appeared in Sensors and Actuators B: Chemical online, May 30, 2020. The work highlights the integration and design of key system components that specifically address challenges associated with wireless sensing within bioreactors.

The paper was written by ECE Ph.D. student Justin Stine; UMD Research Associate Luke Beardslee, M.D., Ph.D., a medical resident at Emory University in Atlanta; alumnus Rajendra Sathyam (M.Eng. Robotics 2019), now at Panasonic Automotive; Professor William Bentley (BIOE/Fischell Institute) and Professor Reza Ghodssi (ECE/ISR).

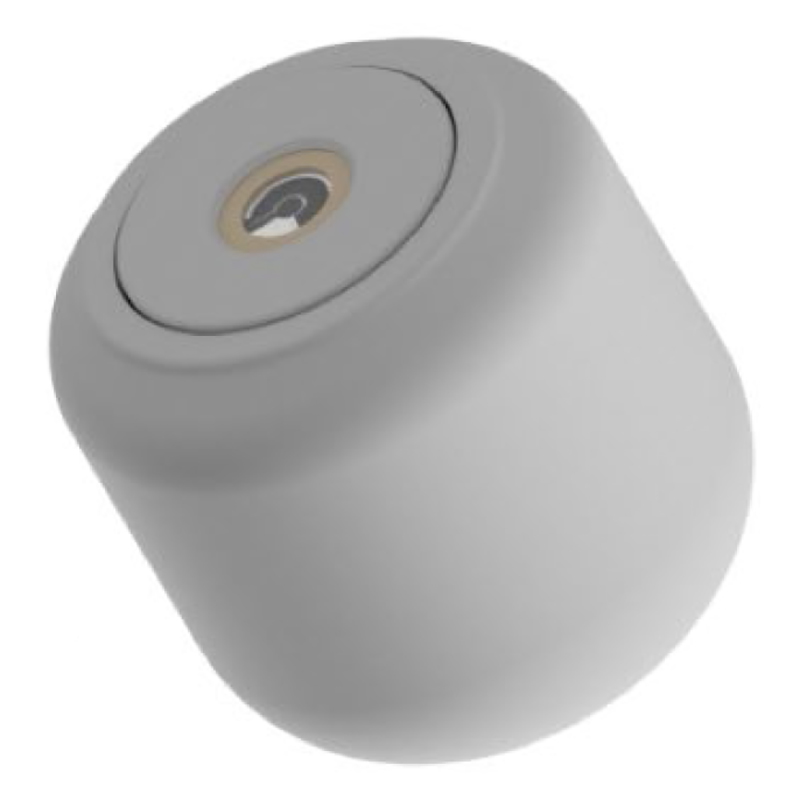

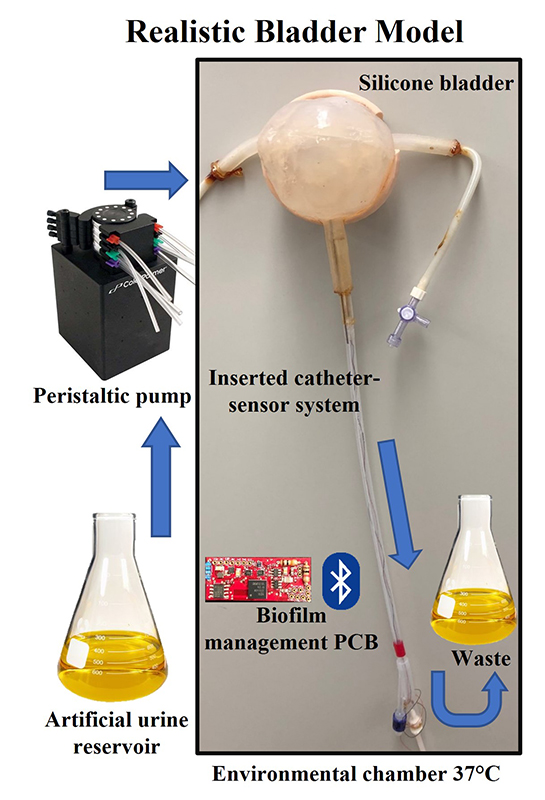

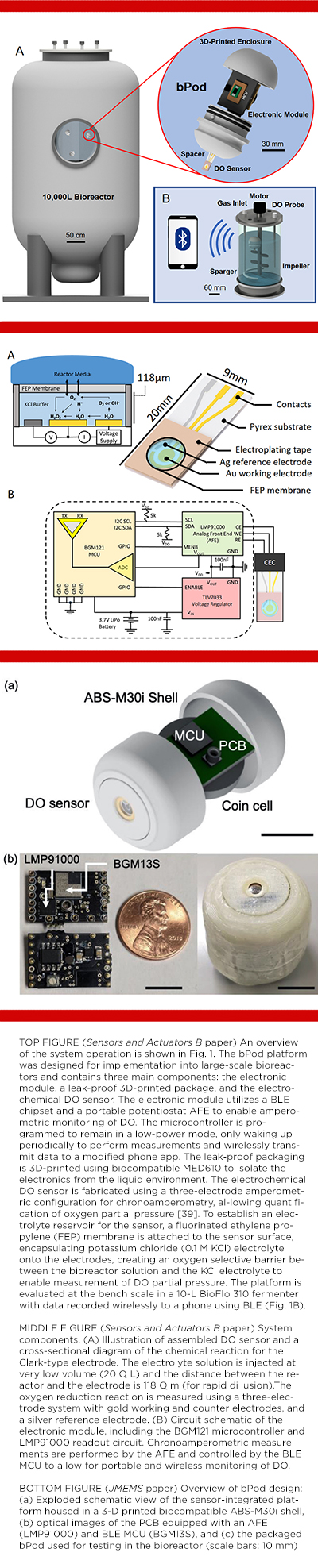

The researchers developed a golf ball-sized bPod capable of real-time in situ monitoring of bioreactor cell culture parameters, such as dissolved oxygen. This bPod is a free-floating, fully-integrated capsule system comprised of a potentiostat analog-front-end (AFE), a chemical sensor, and a Bluetooth Low Energy (BLE) microcontroller that can wirelessly transmit data to a smartphone while submerged in aqueous media. This bPod is intended as a prototype that will be scaled down to less than half the current size for use in lab and pilot scale reactors.

“The bPod is a great example of an embedded sensing system that demonstrates the use of hybrid fabrication and packaging technologies,” says Professor Reza Ghodssi of the Department of Electrical and Computer Engineering and the Institute for Systems Research. “This system makes use of 3-D printing, customized microsensors sensors, and low-power electronics to enable in situ measurements and real-time data extraction in environments that were not previously possible.”

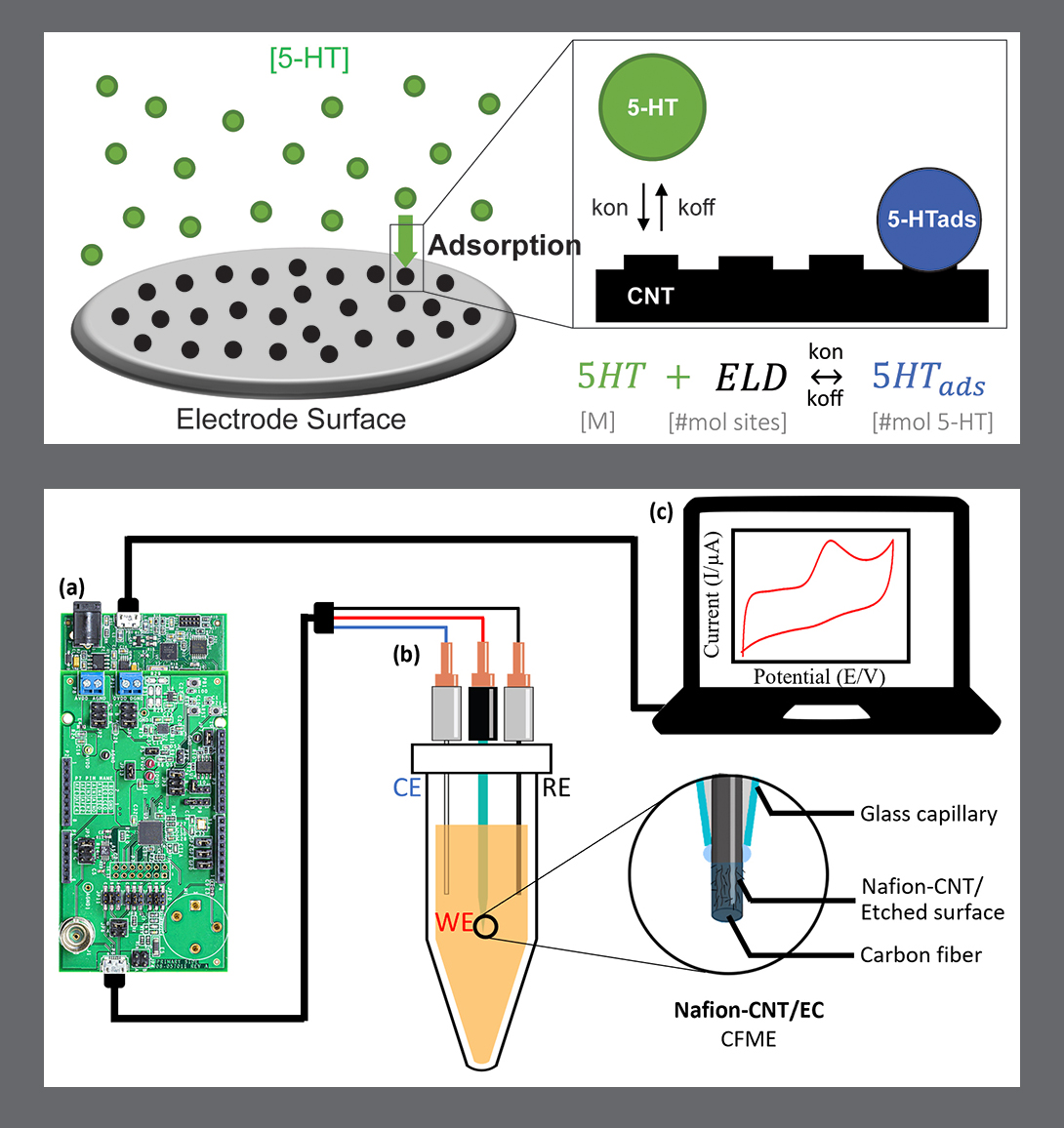

The bPod can be adapted for an array of electrochemical sensors, targeting different process parameters for diverse bioprocess monitoring applications. While the authors envision creating sensors that can measure glucose, glutamine, and lactate in the future, they have started with sensing of dissolved oxygen, owing to its importance in maintaining cell productivity.

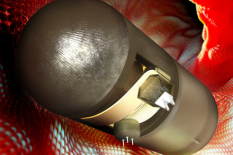

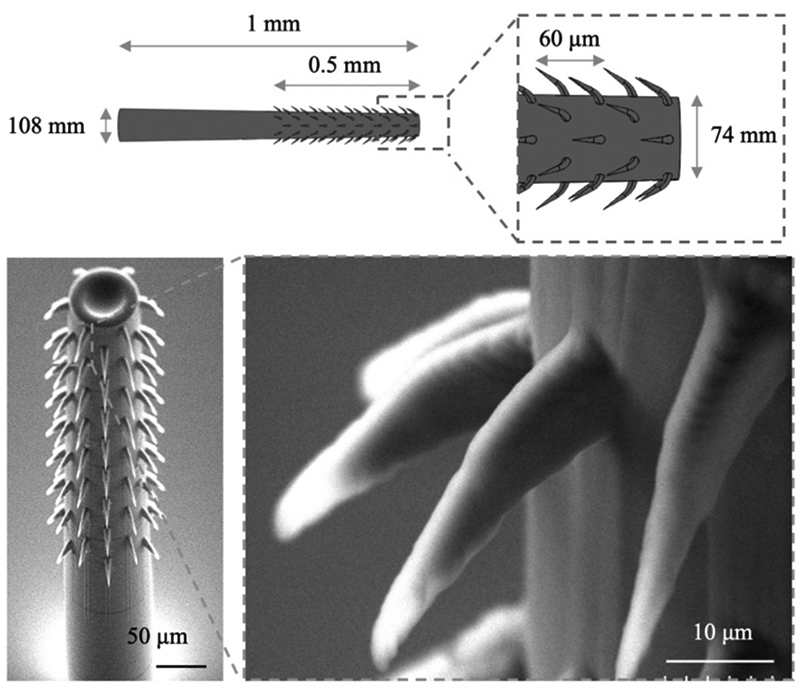

The system is comprised of off-the-shelf electrical components, a carefully designed and assembled Clark-type oxygen sensor, and a 3D-printed housing for leak proof operation. In particular, it utilizes a potentiostat analog-front-end (AFE) paired with a BLE system-in-package (SiP) microcontroller for data processing and wireless data transmission. The AFE is connected to an amperometric electrochemical DO sensor, utilizing microfabrication techniques to achieve a miniaturized Clark-type sensor topology. Electrochemical characterization results in an optimal voltage bias, determined through cyclic voltammetry, allowing real-time chronoamperometric detection of different DO percentages (DO%) using the bPod under dynamically changing sparging conditions in DI water.

The platform represents significant progress towards scalable in situ applications ultimately targeting bioreactor heterogeneity.

A second paper further advances the bPod research chronicled in Sensors and Actuators B. Wireless Sensor-Integrated Platform for Localized Dissolved Oxygen Sensing in Bioreactors was published online in June 2020 in the Journal of Microelectromechanical Systems, and was written by Stine; Beardslee; 2018 EE Ph.D. alumnus and former ISR postdoctoral researcher Sangwook Chu (now at Applied Materials); former ISR postdoctoral researcher Sanwei Liu (now with Boston Scientific); Bioengineering Ph.D. student Dana Motabar; Bentley; and Ghodssi.

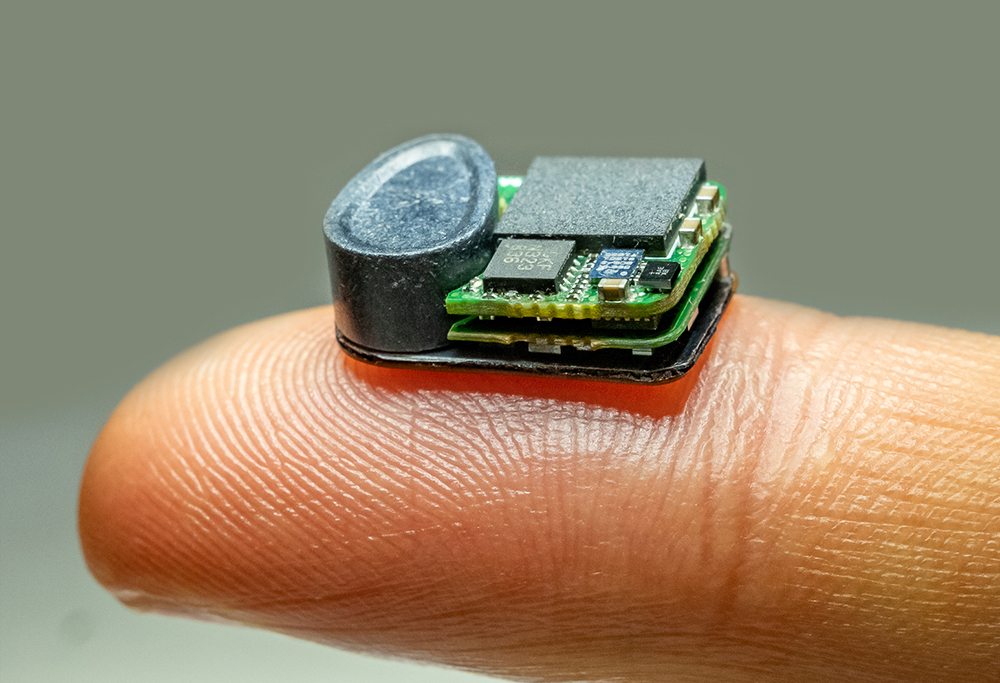

Modifications pursued in this paper were pursued to overcome a number of integration challenges the bPod will face in a realistic bioreactor environment. For example, the bPod needs to have a diameter less than 25 mm, as this is the diameter of process piping inside bioreactors. The bPod also requires a more rapid and reliable electrochemical response to dynamically changing DO saturation relative to the measurement location.

This work significantly advances the PCB-electronics design, DO sensor, and packaging to achieve the overall system miniaturization desired for use in realistic bioreactor environments.

The bPod prototype was reduced in size to a diameter of 24 mm—about the size of a cherry—and was successfully deployed in a 10-L bench-top bioreactor. A gold electrode inside the device was replaced with platinum to generate a much more stable sensor response. The 3D-printed material MED610 was replaced with a more durable, higher impact-resistant material (ABS-M30i) better suited for longer-term operation inside a bioreactor. The researchers also made improvements to the power management of the microcontroller to significantly extend the battery life. Additionally, though not discussed in the paper, pressure and magnetic sensors were added for localization and a new microcontroller was introduced for bluetooth mesh applications.

Future work will include further optimizing power consumption, creating an even more robust package to further improve impact resistance with the bioreactor’s impeller blades, improving the wireless signal as cell growth occurs, and improving sensor stability from bubbles or degradation of the FEP membrane. In addition, the platform will be modified with additional electrochemical sensor types (e.g. temperature, pH, and pressure sensors).

Beyond bioreactors, the bPod sensors could have additional innovative uses.

“We envision a bright future market for the bPod ‘smart marbles,’” Ghodssi says. “We are continuing to investigate and further develop the scaled-down concept of these devices for applications that are targeted toward environmental monitoring, health care, and specialized manufacturing.”

Support: This work is funded by the National Science Foundation-Advanced Mammalian Biomanufacturing Innovation Center, NSF–AMBIC (1841506) grant. The University of Maryland Nanocenter and its FabLab have provided support during fabrication processes. Ben Woodard and the Biotechnology Research and Education Program (BREP) at UMD provide guidance for operating the bioreactor.

Published June 25, 2020